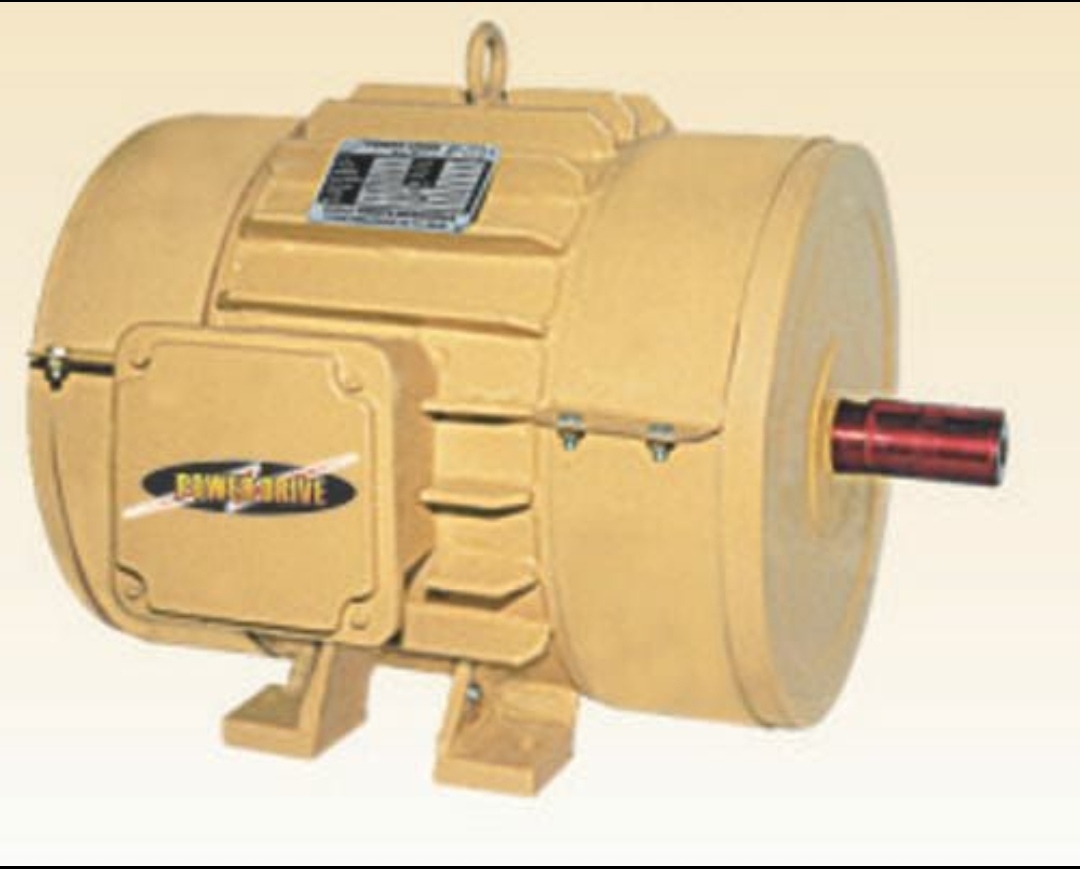

About DC SHUNT MOTOR

This permanent magnet based D.C. Motor has RoHS or CE certification. Its maximum operating speed is 50 rpm and its continuous current is 0.5A. Torque rate of this motor is up to 2Kgf.cm approximately. Operating temperature of this D.C. Motor ranges between -40 degree C to 120 degree C. This low noise system is reckoned for its energy efficient operation, high strength and durable metallic housing and long working life. Speed of this product is adjustable. Gear of this DC powered system is made of metal. Voltage requirement and shaft design of this item can be custom made.

Superior Efficiency for Industrial ApplicationsDesigned to meet rigorous industrial standards, the DC Shunt Motor ensures high efficiency, constant speed under varying loads, and superior reliability. With adjustable speed ranging from 300 to 3000 RPM and high starting torque, it is well-suited for elevating workflows in machinery, elevators, conveyors, and rolling mills. Built with high-grade materials and protected by advanced features, this motor excels in harsh operating environments.

Robust Construction and CustomizationThe motor comes with a sturdy cast iron or fabricated steel frame and supports both open and enclosed sealed types. It meets IP44 and IP55 ratings for dust and water resistance. Customizable shaft diameters, dimensions, and mounting options (foot/flange) allow seamless integration into various setups. Ball or roller bearings and grease lubrication provide smooth operation and minimal maintenance demands.

Reliable Operation and Safety FeaturesOperating on DC power (110V/220V/440V), the motor is equipped with overload and thermal protections to ensure safe and continuous use. With low vibration and noise levels, users benefit from a smoother work environment. It is compliant with IS:4722 and IEC standards, guaranteeing dependable performance backed by manufacturer and supplier support in India.

FAQs of DC SHUNT MOTOR:

Q: How is the DC Shunt Motor used in industrial machinery and elevators?

A: The DC Shunt Motor provides smooth acceleration and consistent speed control, making it ideal for applications such as industrial machinery, elevators, conveyors, and rolling mills where reliability and adjustable speed are crucial for operational efficiency.

Q: What benefits does a copper-wound armature offer in DC shunt motors?

A: Copper-wound armatures increase electrical conductivity, improve efficiency, and reduce energy losses, resulting in enhanced performance and longevity, especially in high-demand industrial environments.

Q: Where can the DC Shunt Motor be installed, and how flexible is the mounting?

A: This motor can be installed in various industrial settings due to its customizable dimensions and mounting options. Foot and flange mounting designs accommodate diverse installation requirements, ensuring compatibility with different equipment layouts.

Q: What process ensures continuous and safe operation of the motor?

A: The motor is engineered for continuous duty (S1), using force-cooled or self-ventilated systems. It features overload and thermal protection mechanisms that prevent operational hazards and maintain smooth, uninterrupted performance.

Q: When should you select a DC Shunt Motor over other motor types?

A: Choose a DC Shunt Motor for applications that require adjustable and constant speed under load, high starting torque, and reliable operation across varied ambient temperatures. It is especially advantageous where precision and efficiency are needed.

Q: What are the key usage conditions and limitations for this motor?

A: The motor operates efficiently within ambient temperatures of -10C to 50C and at atmospheric pressure. Available with open or enclosed sealing and various IP ratings, it is fit for environments where moderate dust and moisture protection are necessary.

Q: How does overload protection enhance the motors operational lifespan?

A: Built-in overload and thermal protection safeguards the motor against excessive current or temperature rise, reducing the risk of damage and extending the equipments service life in continuous duty cycles.

GST : 24AESFS1927A1Z4

GST : 24AESFS1927A1Z4

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese